How to repair a Mercedes-Benz 48V battery control unit with Xhorse Multi Prog?

This case highlights a common but complex fault in modern vehicles, where a simple voltage spike or battery-related event can corrupt the core software of a component, requiring deep electronic intervention rather than simple replacement.

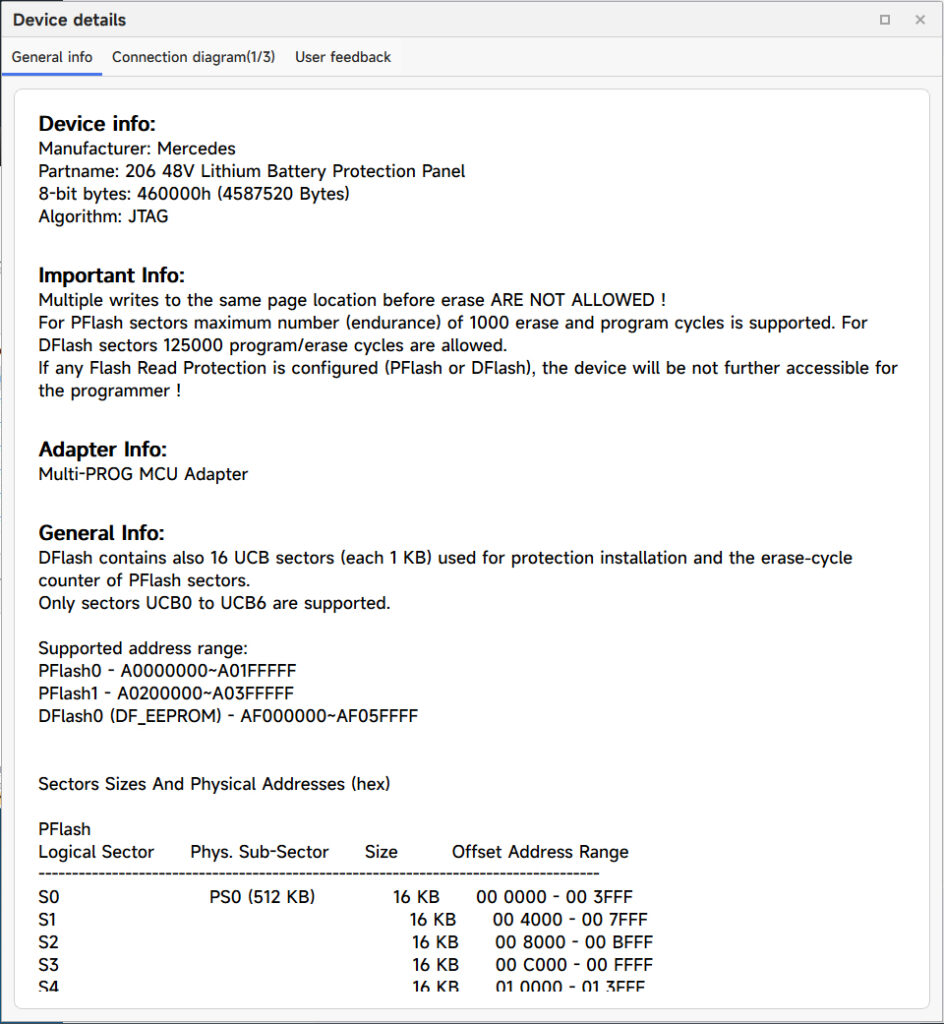

The issue stemmed from a voltage spike, likely during a jump-start or battery replacement, which caused a critical failure. The module’s primary files—P-Flash 1 and P-Flash 2—were corrupted. These files contain the main microcontroller (MCU) firmware. Notably, the corruption extended beyond the main program to the D-Flash (data flash or EEPROM), which stores learned values, adaptation data, and fault histories.

The Repair Process: A Step-by-Step Reflash

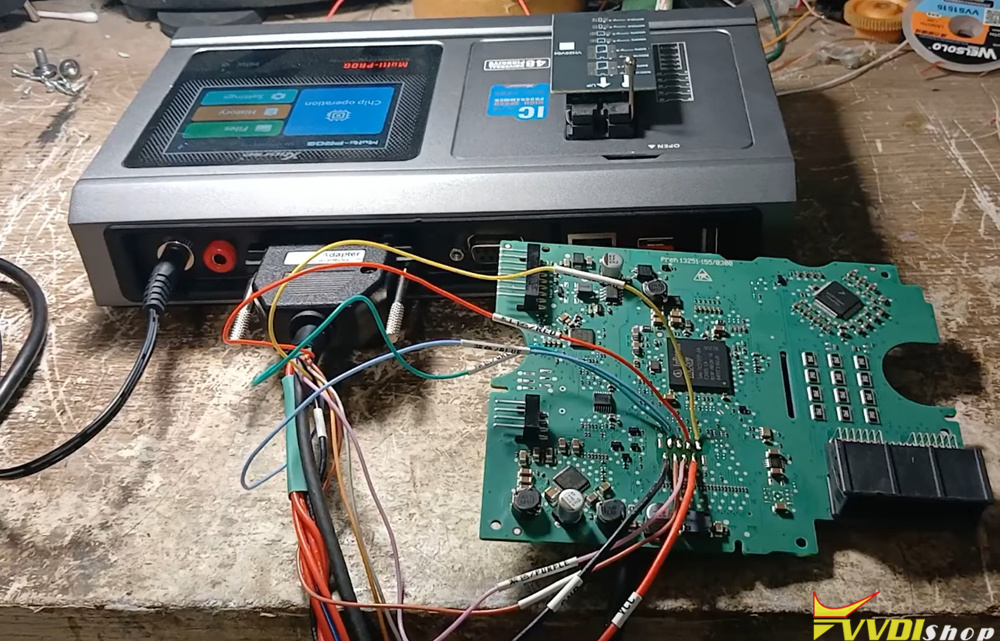

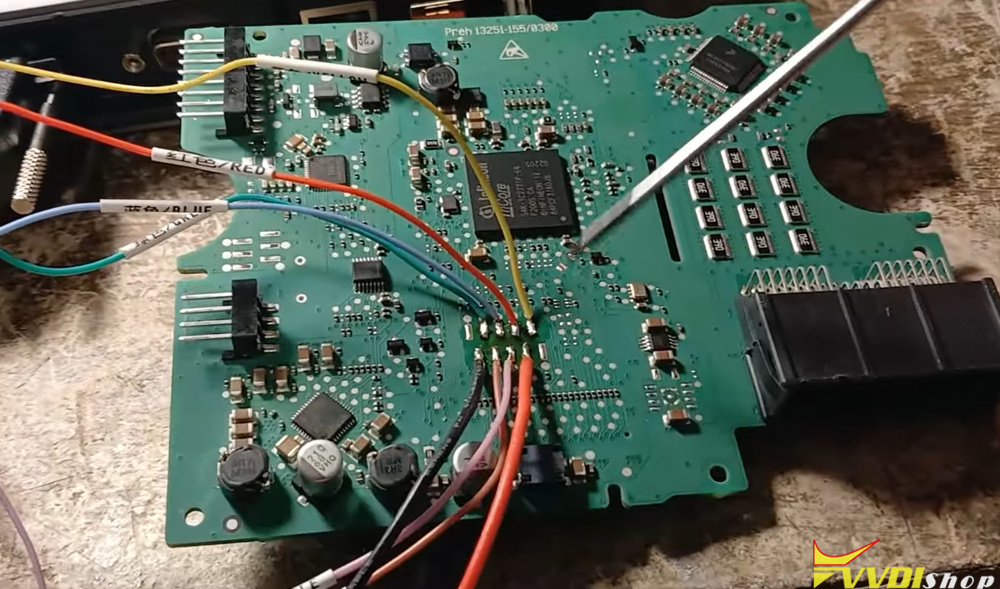

Physical Connection: The module was connected via a dedicated programming interface. We emphasize the importance of accurate wiring, referencing saved pinout diagrams. We noted a discrepancy in official documentation regarding a specific yellow wire’s solder point but confirmed his connection method was reliable based on successful communication.

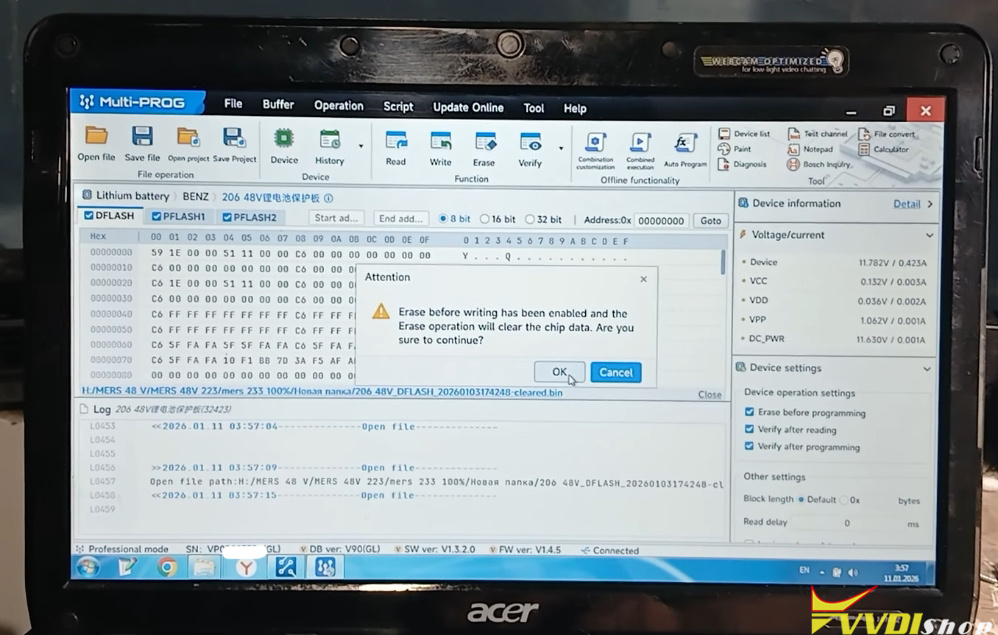

Multi-prog will show how to repair this battery module:

File Preparation and Writing: Three key files were prepared:

- A corrected P-Flash 1

- A corrected P-Flash 2

- A “cleaned” or corrected D-Flash file

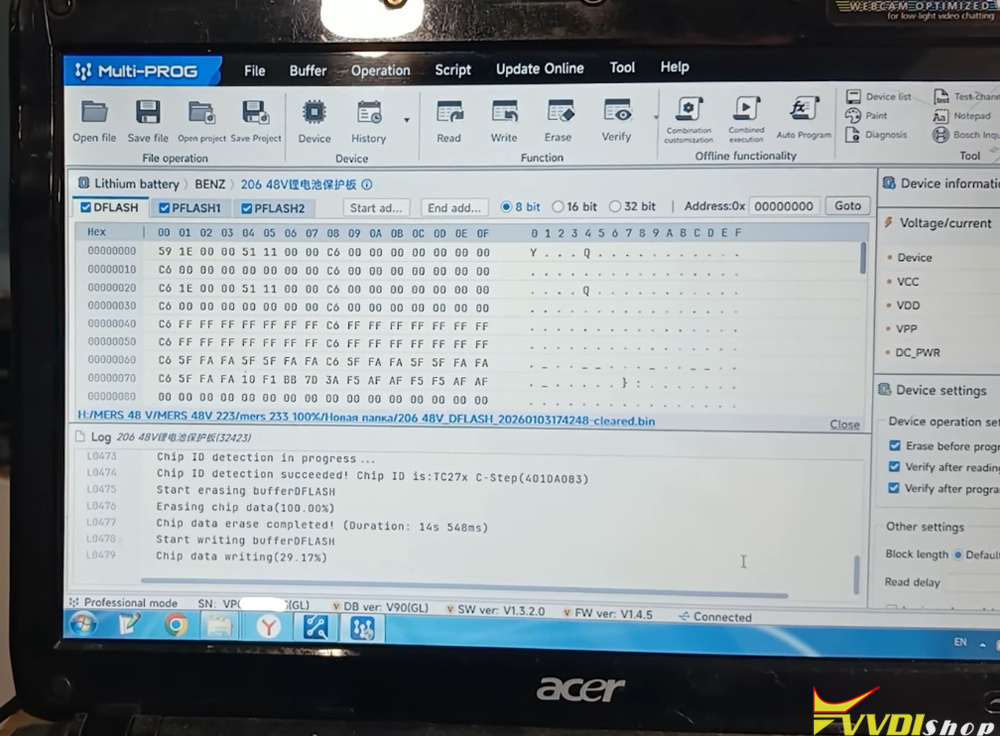

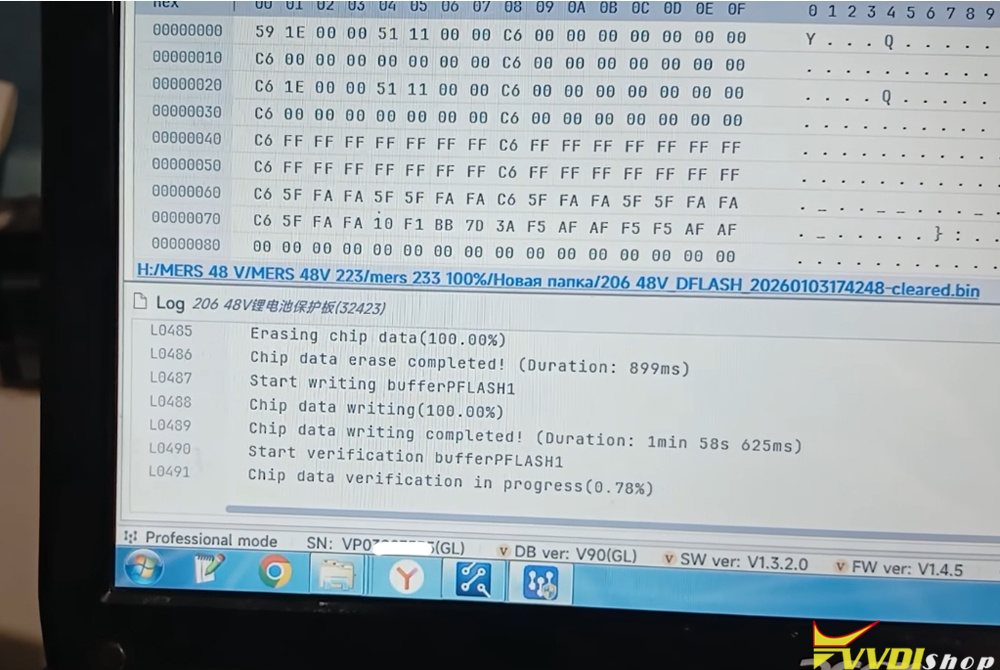

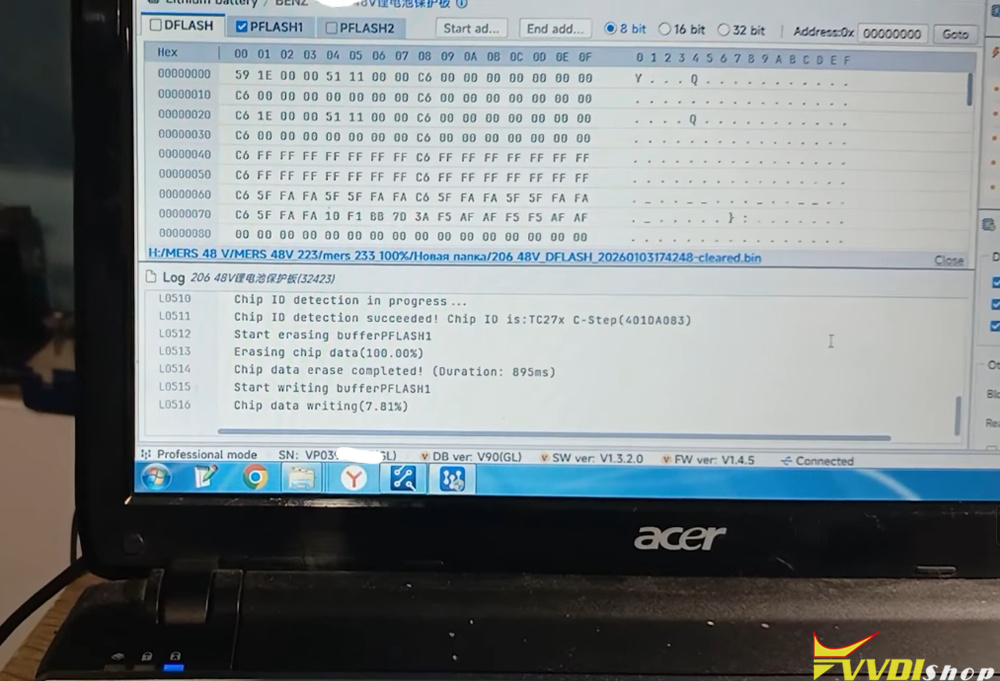

The process began by erasing the old data and sequentially writing the new P-Flash 1, P-Flash 2, and D-Flash files to the module.

Verification is Key: After each write cycle, a verification step was initiated to ensure the data was written correctly and without errors. This step is crucial to confirm the integrity of the repair.

Troubleshooting a Glitch: During the procedure, the process interrupted during the P-Flash 2 verification. Undeterred, we manually restarted the write cycle for that specific file, demonstrating the hands-on problem-solving often required in board-level repair. The process then continued successfully.