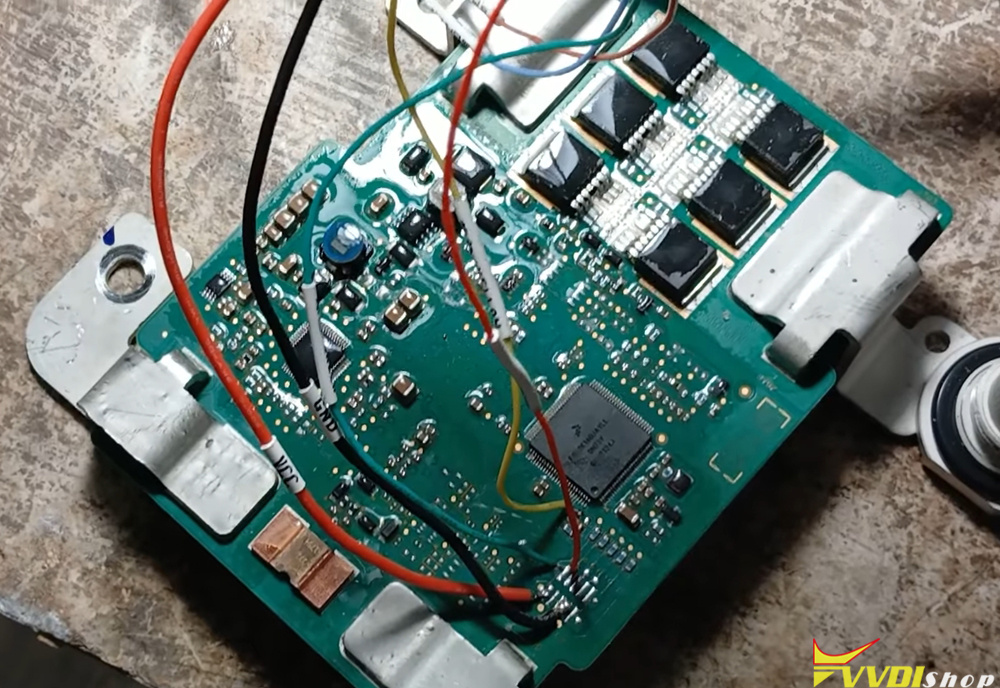

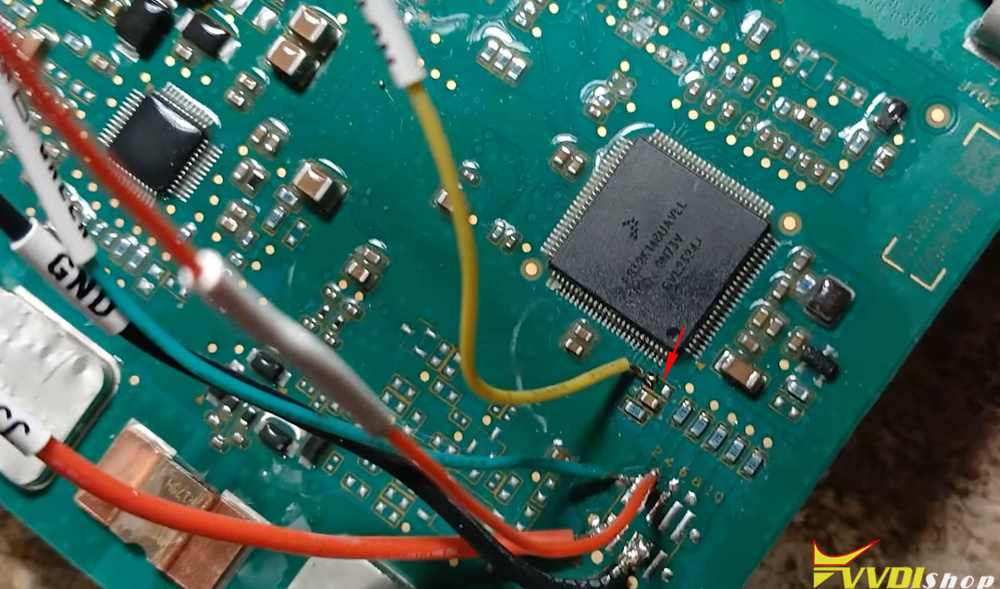

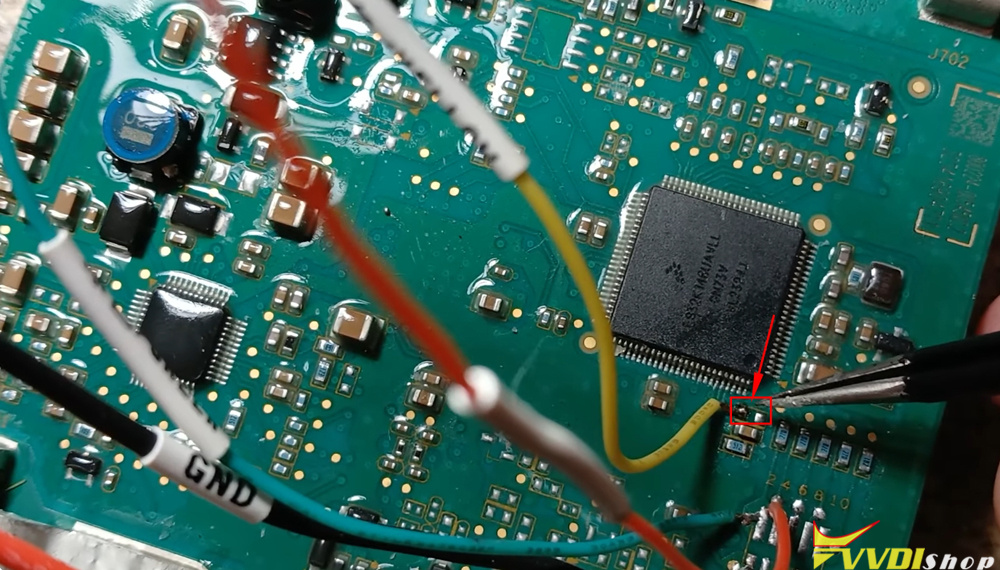

The Li electric car battery’s management system is built around a standard STM32 32146 processor. Connecting the Xhorse Multi Prog programmer (using a multiprobe for accurate pinout: yellow, red, and green wires) seemed straightforward. However, a critical, non-obvious step caused the initial programming failures.

The issue was a pull-up resistor on the reset line. This small component supplies 5V to the reset pin and must be desoldered for the processor to boot into programming mode. Leaving it in place prevents communication with the chip entirely—a key piece of practical knowledge that isn’t always in the datasheet.

Inside the Software: Corrupted Data and a Clean Slate

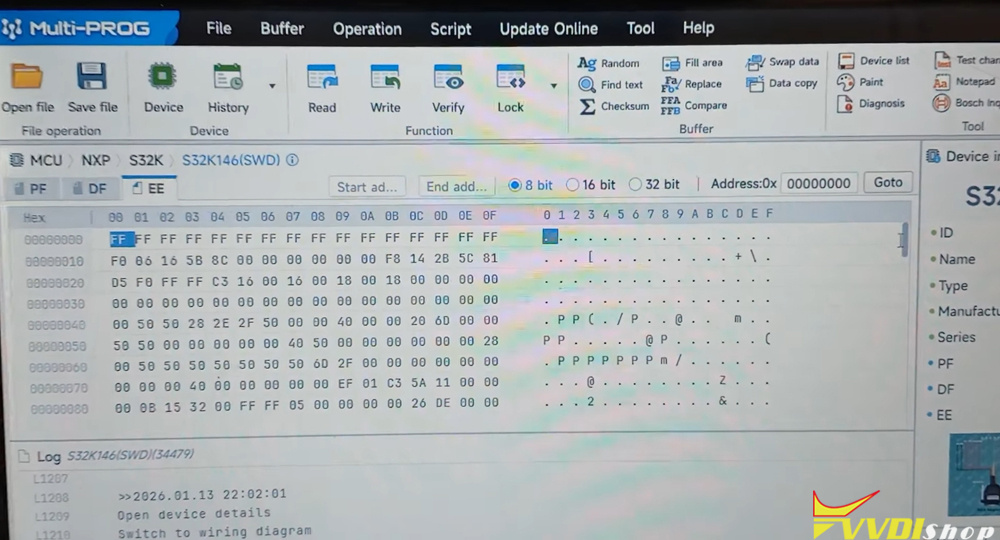

With the resistor removed, successful communication was established. Reading the chip’s memory revealed the root cause: corrupted data in the EEPROM (the non-volatile memory storing critical parameters). The original firmware file also contained multiple Vehicle Identification Numbers (VINs), suggesting the battery had been swapped between different cars in its past.

The repair involved flashing a fresh, clean EEPROM file. This new firmware has a blank VIN field; the battery management system (BMS) will automatically write the VIN from the vehicle it’s first connected to, effectively resetting it to a “virgin” state.

Key Takeaways for Technicians

Look Beyond the Obvious: Correct wiring is just the first step. Understanding the specific board’s design and potential boot-blocking components is crucial.

The Reset Resistor is Key: desoldering the pull-up resistor on the reset line is mandatory for programming access.

EEPROM Corruption is a Common Failure Point: Physical battery cells might be healthy, but corrupted configuration data can brick the entire pack. Reprogramming with a clean file is often the solution.